- Home »

- Product Landing Pages »

- Pistons

Pistons

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incid.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incid.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incid.

Pistons are the backbone of any true hardcore racing engine and that’s where CP-Carrillo excels.

Pistons

Representing CP-Carrillo in the highest way possible by wearing apparel and showing off as the newest sponsored rider for this race season. Excited... More Info »

Hunter Jones

As every good result is a sum of its parts, your pistons are a critical component, so thank you, from myself & our crew, for your continued effort... More Info »

Clif Bakx

After pushing the limits of our Subaru engines for over a decade, beyond what event the engineers from Subaru in Japan dreamt possible, we finally... More Info »

ALI AFSHAR

I want premier parts powering my racing engine. That's why I use Carrillo Rods. You can't outperform them! Austin Prock Austin Prock... More Info »

Austin Prock

CP- Carrillo has been a fantastic company for me to deal with and will always receive my highest recommendation for anyone needing pistons and or... More Info »

Bill Ross

Our recent success in the small block drag race engine arena is in large part due to CP pistons and Ric Pennington's help in constantly refining... More Info »

Bob Book

Our engine builder, Tom Negrete, has been using CP pistons & Carrillo rods in our open UMP/USMTS modified engines for over a decade without a... More Info »

Bob Stephens

When we're turning our Garrett Racing engines 8400 rpms night in, night out for 90 races a year. There's only one brand connecting rods that will... More Info »

Brian Brown,

The combination of the CP and Carrillo Rod have helped me succeed in winning four straight National Championships with zero DNFs. I am happy to be... More Info »

Chad Wienen

CP-Carrillo is BASICALLY the best in the business. The products they offer are top notch, the people they employ are second to none, and their... More Info »

Dave Schenker

Design and engineering is top notch and has contributed to our success over the last few years: 2 Championships in TFH! Products are far superior... More Info »

David Kirkland

CP-Carrillo is the back bone of our engine program. At 6.72@221 mph in ProStreet and 6.50@227 mph in Pro Open D.M.E. Racing and CP Carrillo are... More Info »

DME Racing

We at EKR are proud to have been partnered with CP-Carrillo from the inception of their top fuel connecting rods as well as their pistons. We have... More Info »

Eddie Knox

With CP-Carrillo Pistons and rods in my Polaris RZR 1000, we have charged to a 4 race win streak! I couldn't be happier with the smooth consistent... More Info »

Eric and Lacrecia Beurrier

Why do we choose CP-Carrillo? It’s a very simple answer. They are the best in the business at what they do. Every part we have ever received... More Info »

Greg Neal

For the past 12 years HTP performance has been breaking records, winning races, and championships . HTP was the first Real street bike to break the... More Info »

HTP Performance

Today I ran into a CP box in our warehouse, just looked into and saw these beautiful pistons, like a piece of art. Thanks for our partnership.... More Info »

Jaap Mensinga

CP /Carrillo’s proven track record is what makes me so proud to represent them. Stroll through the pits at any race and you will see their logos... More Info »

Jake Gavio

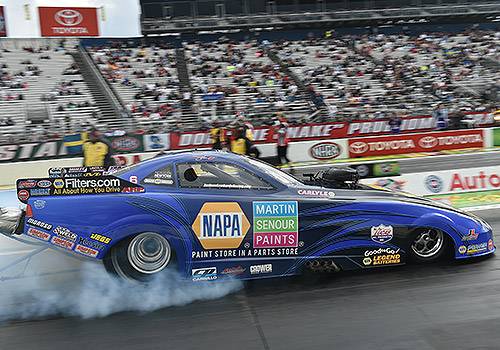

We rely on CP-Carrillo for products made to withstand the rigors of a nitro engine. CP Pistons have been an integral part of our 5.5-second,... More Info »

Jason Rupert

If you want the best go to CP-Carrillo. When I was in a pinch they overnight-ed me a set of pistons to get me back into the race. Their pistons and... More Info »

Jeff Jones

I've been a CP-Carrillo dealer for years and their innovation and attention to detail is why. They are always looking for the best product. For my... More Info »

Jeremy Shaw

CP Pistons have served Jackson Lombardo Racing well, but never better than in 2015! Seven for seven in final rounds, back to back Jeg's victories,... More Info »

John Lombardo Jr.

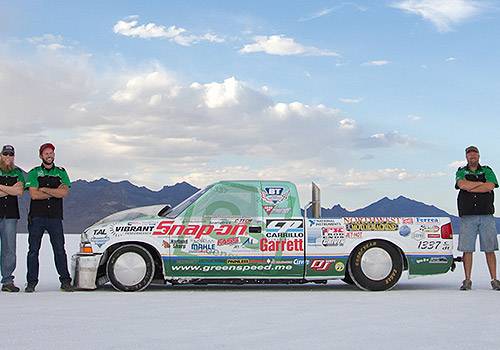

Since 2010 we have used CP/Carrillo in both of our record holding race cars. CP-Carrillo has been a key partner throughout the years and have... More Info »

Kings Performance

Every engine that leaves my shop has CP pistons in it for more than several reasons. #1 reason is customer support, I often feel like I'm dealing... More Info »

Matt Hasara

Mike Follmer and his R&D Factory Yamaha FZR. Uses CP Pistons and Carrillo Rods to take him to victory in the IJSBA Offshore Endurance series.... More Info »

Mike Follmer

n 2008, while preparing a new Pro Stock engine program for Mike Edwards, I decided to step out of the box, and approached CP-Carrillo about piston... More Info »

Nick Ferri

CP-Carrillo has been extremely helpful in our racing program. They've continued to improve the construction and design of their products,... More Info »

Norm Grimes

Been using the CP-Carrillo Bullet Piston for over a year now in my twin turbo 403 ci LS with E85. These 14cc dish pistons gave me a static... More Info »

Quentin Feast

Texas Bounty Hunter P/M 411, 5x ProMod Champion has used CP-Carrillo for the last five years, with a 0% failure rate. Could not be more pleased... More Info »

Randy Benson,

Monster Energy Kawasaki Racing Team appreciates the support that CP-Carrillo continues to offer. With your support we have achieved a goal... More Info »

Reid Nordin

CP-Carrillo have been part of our racing program since 2009. They helped us achieve many goals in competing in the very competitive class called... More Info »

Rolando Blanco & Allan Jimenez

“I want to let you know that I have never put a set of pistons and rods in as good as yours right down to how they are packaged and tolerances.... More Info »

Russ Morseman

I wouldn't use any other connecting rod on my Top Fuel Dragster but a Carrillo. I couldn't ask for anything more from a rod. They are the most... More Info »

Terry McMillen

Thank you CP-Carrillo for custom building my hot rod's pistons! The best pistons and rods and the best service in the business. Nothing but CP for... More Info »

Tony Scarlatta

Just wanted everyone at CP-Carrillo to know how much we appreciate what you all have done to help me personally have a successful race season. I... More Info »

Vic Hill