FeaturesCoatings

-

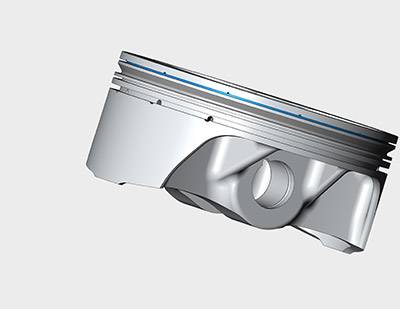

ASF Treatment

Besides the obvious shine, ASF (Accelerated Surface Finishing) deburrs and smoothes the surface which reduces

carbon build up, possibility of stress risers and also aids in shedding oil from the piston underside. There are different

approaches that can be taken, either the entire piston can be treated, or just the dome and underside depending on

when the process takes place.

ASF Treatment

Besides the obvious shine, ASF (Accelerated Surface Finishing) deburrs and smoothes the surface which reduces

carbon build up, possibility of stress risers and also aids in shedding oil from the piston underside. There are different

approaches that can be taken, either the entire piston can be treated, or just the dome and underside depending on

when the process takes place.

-

Ceramic Crown Coating

This coating reflects heat into the combustion chamber and away from the piston crown, while lowering piston

temperatures for increased part life. The engine can experience improved combustion and performance as a result of

heat being reflected back into the fuel charge.

Ceramic Crown Coating

This coating reflects heat into the combustion chamber and away from the piston crown, while lowering piston

temperatures for increased part life. The engine can experience improved combustion and performance as a result of

heat being reflected back into the fuel charge.

-

Hard Anodize

Anodizing the piston reduces wear and material transfer. Anodizing can be done to the entire piston or a selective

area depending on its usage. Anodizing the entire piston has been shown to be very durable in drag racing

applications.

Hard Anodize

Anodizing the piston reduces wear and material transfer. Anodizing can be done to the entire piston or a selective

area depending on its usage. Anodizing the entire piston has been shown to be very durable in drag racing

applications.

-

Skirt Coat / Moly Dry Film Coating

The application of molybdenum to the piston skirt, used to reduce friction between the piston and the cylinder during

engine operation. It also helps during cold start ups and high temperature operation where a substandard oil barrier

on the cylinder wall could exist.

Skirt Coat / Moly Dry Film Coating

The application of molybdenum to the piston skirt, used to reduce friction between the piston and the cylinder during

engine operation. It also helps during cold start ups and high temperature operation where a substandard oil barrier

on the cylinder wall could exist.

-

Top Ring Groove

Some pistons require only the ring groove(s) anodized in order to lessen the chance of micro- welding the ring to the aluminum groove.

Top Ring Groove

Some pistons require only the ring groove(s) anodized in order to lessen the chance of micro- welding the ring to the aluminum groove.

-

WPC Treatment

WPC is a treatment that enhances the surface to reduce friction by firing ultra fine particles towards the surface of a

piston or wristpin at very high speeds. The thermal discharge permanently changes the surface, strengthening the

structure and creating a harder more durable final product. Its unique micro-dimple formation pattern greatly reduces

friction and helps retain oil.

WPC Treatment

WPC is a treatment that enhances the surface to reduce friction by firing ultra fine particles towards the surface of a

piston or wristpin at very high speeds. The thermal discharge permanently changes the surface, strengthening the

structure and creating a harder more durable final product. Its unique micro-dimple formation pattern greatly reduces

friction and helps retain oil.